Cooling Tower Fill - Heat Transfer Surface Inside Tower

Cooling tower fills are vital components in the heat transfer process of cooling towers, which act as the media over which the hot water is distributed as it is being cooled. Their primary function is to put as much water surface area in contact with as much air for the longest amount of time possible. The fill packs are the heart of an evaporative cooling tower.

Due to almost constant exposure to high temperature water, cooling tower fills are the most possible to wear and tear compared with other cooling tower components. That is to say, upgrading the cooling tower packing by constructing with robust and non-clogging materials could extend the life of a cooling tower, which tends to be the simplest and most cost-effective way to reduce tower maintenance downtime.

What is a cooling tower?

Cooling tower is a heat exchanger or heat rejection device, inside of which heat is discharged from the water by contact between the water and the air. Hot water from the system enters the cooling tower and is distributed overspread the fill, through which the air is forced, causing a small portion of the water to evaporate. This evaporation removes heat from the remaining water, which is collected in the cold water basin and returned to the system to absorb more heat. There are patterns on the fill which are called flutes, to help control how the water flows and keep it at the expected flutes for the evaporation to happen at the rate the tower operator is looking for.

Cooling tower may be designed to operate either in counter flow and cross flow mode. In counter flow cooling towers, the water flows vertically down the fill as air flows vertically upward. Whilst in cross flow cooling towers, the falling water flows vertically down the fill as air enters along the entire height of the structure and flows horizontally across.

Choosing a cooling tower fill

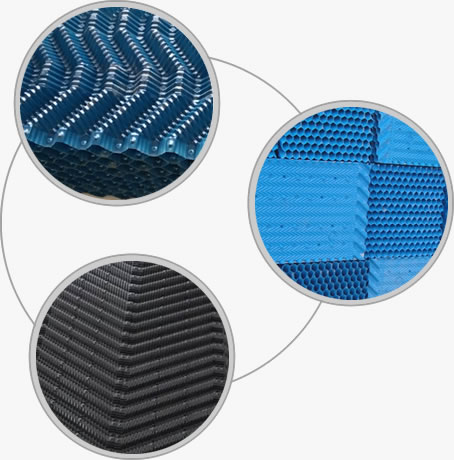

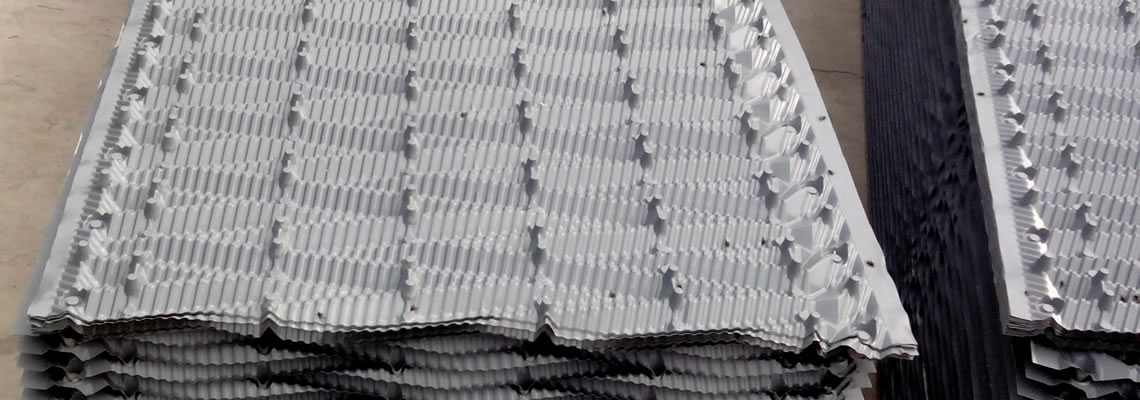

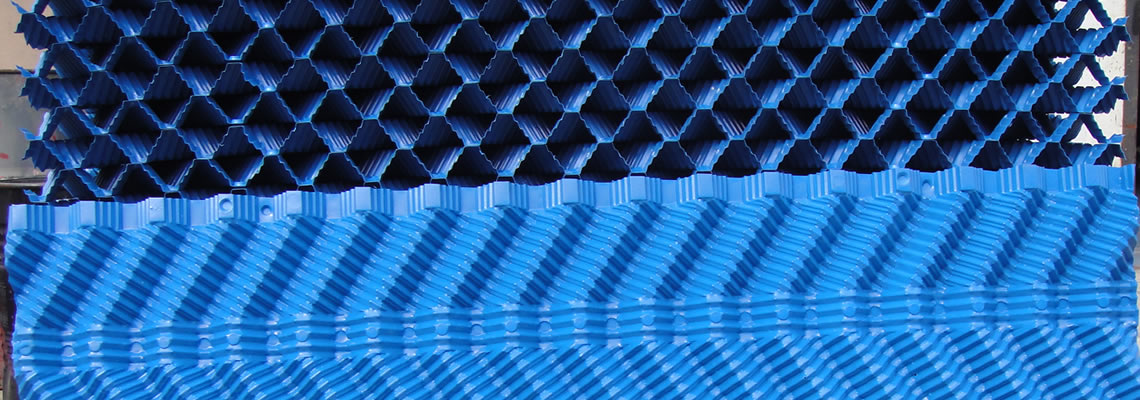

We offer various types of cooling tower fills, for example, round cooling tower fills, s wave cooling tower fills, cooling tower vertical flow fill, offset fluted fills, herringbone fills, cross fluted fills and special cooling tower fills. They are used in a wide range of industries wherever machinery and equipment are cooled with water during production cycle, such as energy, iron and steel, chemical, petrochemical, mining, food, service trade (hospital, subway, cinema), textile, etc.

There are a lot of factors that influence the selection of a particular cooling tower fill for a specific application, such as the materials of fills, performance of the cooling tower system, impact of water treatment chemistry on the overall operation, etc. So before making the final selection, consult a cooling tower manufacturer to make sure that the fill is with the best thermal performance, and a water-treatment specialist, who could recommend the appropriate treatment chemicals to minimize settlings. Together they can help you determine what your facility needs and how to achieve long fill life and efficient fill performance with minimum maintenance.

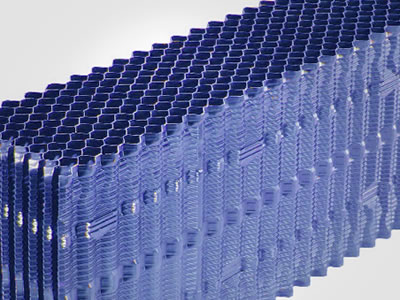

Cross Fluted Cooling Tower Fills

Cross Fluted Cooling Tower Fills

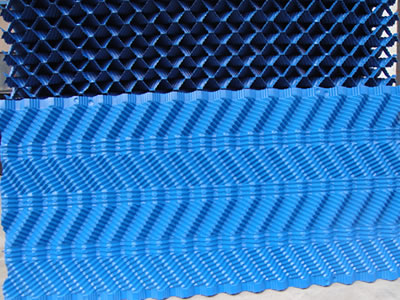

S Wave Cooling Tower Fills

S Wave Cooling Tower Fills